Latest Insights in the Evolving Digital World

The Machine Vision Team

by Andrea Mustine, IQS Editor

As children we learn that there is no “I” in “team,” a concept that teaches us to think unselfishly and use our individual skills for one common goal. As adults, those of us who venture into the business realm learn quickly that no company can thrive when every member of the staff is a lone wolf. Success depends on communication and a common vision. The same is true of many of the systems used in the manufacturing industry, such as machine vision. Regardless of how technologically advanced and impressive each piece of machinery is, it must function within the larger context of a full machine vision system to reach its full potential. A comprehensive look at what machine vision is and why the individual parts must work together as a team to make the manufacturing industry more efficient, less expensive and safer for workers will reinforce what has been drilled into our heads since we were small; it’s better to have a team then to go it alone.

Machine vision could have been developed from an obscure science fiction story in the 1950’s; it is that cool. Although it is utilized in commercial digital cameras as facial recognition software, its main function is industrial. Able to capture images by emulating human sight, the machine vision system interprets these images to collect data. Functioning as an autonomous robot, sometimes even with robotic arms that respond to certain visual stimuli, machine vision is used to inspect and sometimes correct mistakes in the manufacturing process. For example, because mass production is done with die casting processes, they require repeated inspection throughout to ensure that if a mistake is being made it is caught before hundreds or thousands of parts are manufactured incorrectly. Depending on the context, multiple machine vision systems may be in use to monitor different sections of production.

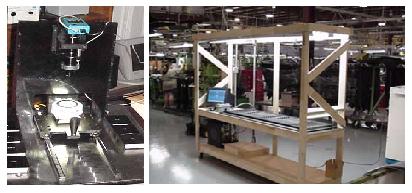

Machine Vision Photos Courtesy of Decision Technology LLC.

Although most machine vision systems are custom made for individual companies, there is a basic list of components that function together as a machine vision team. Vision sensors, which are triggered when a product or part crosses their path, are the front men of the team. They are the first to make contact with the product, and they trigger the next member to follow through with the next step, which is the camera or imaging device that works in congruence with a lighting device. These two are activated simultaneously, capturing a clear digital image of the product that is then processed through another machine vision team member, the frame grabber. The frame grabber translates the digital image into data that it inputs into a computer system, which is the brains of the whole organization. The machine vision software within the computer system is able to identify, measure, count or inspect the image according to the pre-set program designed by the company, and it is sometimes set-up to make physical changes in response.

All of these parts work together to do an incredibly cool thing: keep a diligent and corrective eye on production, saving manufacturing companies significant amounts of money since major mistakes are being avoided. Another benefactor of the machine vision teamwork is the manual laborers working alongside them. Rather then being forced to perform the mundane tasks the machine vision can apply to, fewer workers are able to perform more mentally stimulating jobs in the industry. Also, certain elements of manufacturing lines can be dangerous, and the machine vision is able to step in safely where a human worker might get hurt. The machine vision team lives up to every expectation that working together demands; it contributes to safety while doing excellent work and retaining an element of cool that other mechanical products will always envy.